Thermech History

Perfecting Surfaces Since 1949 •

(714) 533-3183 info@thermech.com

Thermech History

Thermech’s Rich History

Thermech began in 1949 when a confident salesman named Charles “Rip” Ripley and a mechanically savvy partner named Ray Hansel founded Imperial Coatings in Downey, California and became the exclusive provider of Platon (liquid neoprene) in the Southwest. Imperial Coatings sprayed Platon onto World War II ships to preserve them from the corrosive effects of salt water. With permission from the military, DuPont declassified polytetrafluoroethelyne (PTFE, later branded as Teflon) and developed PTFE-based coatings that effectively resist corrosion and high temperatures. Imperial Coatings developed commercial markets for PTFE coatings.

In 1957 Imperial Coatings moved to its present facility in Anaheim, California and two additional investors joined the company: Richard “Dick” Harris, a chemical engineer, and Jack Walker, a mechanical engineer with a proven sales track record with the military. Thermech’s other two directors brought technical experience in plastic coatings. Imperial Coatings changed its name to Thermech Engineering Corporation and focused on coatings with special thermo-mechanical properties. Under Dick’s guidance, a number of proprietary coatings were developed, some of which NASA still uses. Additionally, Thermech developed the capability to work with raw fluoropolymer powders. To support growth, Thermech developed the ability to perform ram extrusion and the highly technical molding and machining of thermoplastics. At first, the company concentrated on high-volume items such as Teflon Backup Rings, but later began selling seals and O-rings to chemical companies and to the military for use in rockets and missiles.

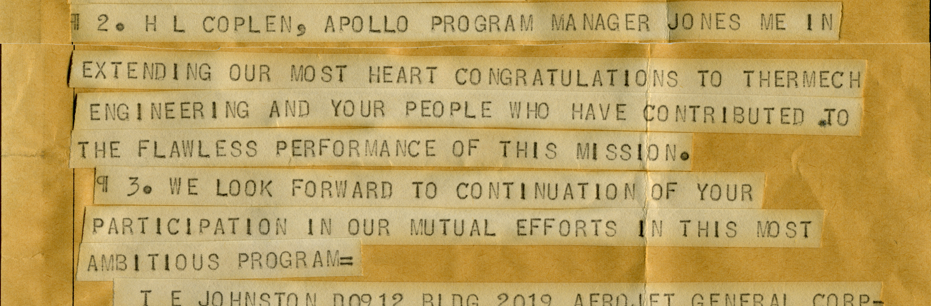

In the 1960s Thermech was asked to join America in the Space Race, and the company switched to the production of more sophisticated items such as Cryogenic Aerospace Seals that are representative of Thermech’s present-day high-quality capabilities. Thermech entered into MIL-SPEC type operations and began the precision production of aerospace parts using specialty fluoroplastics such as KEL-F and Teflon-based materials. Thermech made KEL-F Cryogenic Seals for the liquid H2 and O2 tanks on Saturn booster rockets. Thermech also provided a number of parts for the Apollo-series rockets, including the maiden voyage and the Lunar Lander. Thermech used one of its proprietary compression-molding materials, TEC-fluorfil BF1, to make the main seals for the storable propellant used in the engine of the Apollo Capsule that went to the moon.

In the 1970s Thermech was asked by the United States Air Force to participate in the development of parts for a series of aircraft including what became the Stealth Bomber. Thermech also expanded into coating items as diverse as videotape-making machines and pizza-warming plates.

In the 1980s Thermech developed a unique method to coat the inside of narrow tubes with inside diameters as small as 0.007 inches (0.178 mm). These tubes are commonly used for probes on medical diagnostic devices or as microcatheters for endovascular instruments.

In 1995 Thermech purchased Premium Plastics, whose key businesses were coating molds and printer rollers. From this acquisition, Thermech developed a commercial products group to service the higher-volume, price-sensitive market.

In 2003 Thermech became part of the Symbex Companies, joining a group of like-minded companies focused on customer service, value creation and growth.

In 2009, Thermech expanded its operations and commercial products group. In addition to the molds and printer rollers, Thermech started coating trays, pans and other equipment for commercial bakeries located in the Western United States.

Teflon® Coating / Spray Coating

Chemours Teflon Industrial Licensed Applicator

Whitford Licensed Applicator

PI / Vespel®

PPS / Ryton®

PES

FILLERS

THERMECH COATINGS

TECfluorcote

TECthermcote

DUPONT™ COATINGS

Teflon® PTFE

Teflon® FEP

Teflon® PFA

Teflon® One Coats

Teflon® PTFE/PFA Blends

WHITFORD® COATINGS

Xylan®

Xylan® XLR

Eclipse®

Dykor®

Xylar®

Halar® ECTFE

Teflon® ETFE

Teflon® FEP

Teflon® PFA

Ryton® PPS

PTFE Etching and Bonding

Home | Quality | Contact | About | History | Aerospace Coatings | Medical Device Coatings | Non-stick Commercial Bakery Coatings

Mold Release Coatings | Teflon® Coatings | Powder Coating | Compression Molding | Spray Coating Materials

Powder Coating Materials | Compression Molding Materials | Privacy Policy | Terms of Use | ©2010 Thermech Corporation. All Rights Reserved.

Teflon® is a registered trademark of E.I. du Pont de Nemours and Company used under license by Thermech Corporation. Only DuPont makes TEFLON®.

1773 West Lincoln Avenue, Building I • Anaheim, California 92801