Non-Stick Pan Coatings

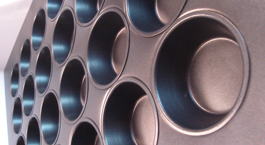

Before

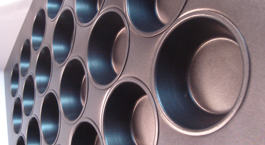

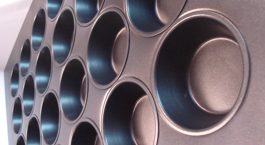

After

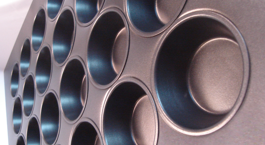

After

Before

We Coat:

-

•baguette screens

-

•shim skins for tortilla presses

-

•pans

-

•trays

-

•chutes

-

•chocolate molds

-

•rollers

-

•conveyor rollers

-

•hoppers

-

•mixer paddles

-

•probes

-

•heat-sealing bars

-

•pie pallets

-

•pizza trays

-

•cookie trays

-

•cheese molds

-

•measuring instruments

-

•griddles

Thermech provides the finest range of FDA-approved non-stick release coatings for bakeware and other food manufacturing equipment. Among the many advantages of Thermech’s pan coatings, our coatings eliminate the need for expensive and messy silicone glazing and release oils. The nonstick fluoropolymer coatings we apply to commercial baking pans are specifically formulated to withstand the heat and humidity of baking and are far superior to those used in consumer products.

Call Us for Samples

We work with our customers to develop the most appropriate coatings for their products. If you would like us to coat bakeware samples to test on your lines, call us at (714) 533-3183 or email us at info@thermech.com.

Fast Turnaround

Downtime costs money, but you don’t want to carry more bakeware inventory than absolutely necessary. What do you do? Turn to Thermech, of course. We can coat your bakeware and return it to you quickly. Your pans may still be warm from our curing ovens.

We burn off excess coatings at high temperatures, and then we sandblast the surface to prepare it for coating. We apply multiple layers of our proprietary coatings, including a protective top coat that ensures the longest lasting, best performing surface possible. Finally, the coatings are baked on in our ovens. We can coat new pans, strip and recoat coated pans, or strip and coat glazed pans.

Over time, compared to silicone glazing and non-stick sprays, Thermech’s food-grade coatings save you money. Recoating does not have to be done nearly as often as reglazing, and by eliminating secondary release agents and oils, far less cleaning is required.

Perfecting Surfaces Since 1949 •

(714) 533-3183 info@thermech.com

Non-Stick Pan Coatings

Teflon® Coating. Compression Molding of Teflon® PTFE, PFA, FEP, Tefzel®,

Kel-F®, VICTREX®, Vespel®, Ultem®, Torlon®, Ryton®. Plastics Machining. Since 1949.

Teflon® Coating / Spray Coating

Chemours Teflon Industrial Licensed Applicator

Whitford Licensed Applicator

PI / Vespel®

PPS / Ryton®

PES

FILLERS

THERMECH COATINGS

TECfluorcote

TECthermcote

DUPONT™ COATINGS

Teflon® PTFE

Teflon® FEP

Teflon® PFA

Teflon® One Coats

Teflon® PTFE/PFA Blends

WHITFORD® COATINGS

Xylan®

Xylan® XLR

Eclipse®

Dykor®

Xylar®

Halar® ECTFE

Teflon® ETFE

Teflon® FEP

Teflon® PFA

Ryton® PPS

PTFE Etching and Bonding

Home | Quality | Contact | About | History | Aerospace Coatings | Medical Device Coatings | Non-stick Commercial Bakery Coatings

Mold Release Coatings | Teflon® Coatings | Powder Coating | Compression Molding | Spray Coating Materials

Powder Coating Materials | Compression Molding Materials | Privacy Policy | Terms of Use | ©2010 Thermech Corporation. All Rights Reserved.

Teflon® is a registered trademark of E.I. du Pont de Nemours and Company used under license by Thermech Corporation. Only DuPont makes TEFLON®.

1773 West Lincoln Avenue, Building I • Anaheim, California 92801