Medical Coatings

Perfecting Surfaces Since 1949 •

(714) 533-3183 info@thermech.com

Medical Coatings

Medical Coatings

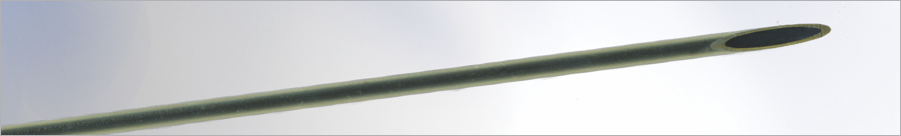

Since 1982, Thermech Engineering has applied PTFE coatings to the ID of narrow tubes—as narrow as 0.007” (0.178 mm). We specialize in ID coatings and are the only company capable of coating such narrow hypotubes. We originally developed this technology to coat in vitro diagnostic probes. Since then, Thermech has become a market leader in narrow-diameter ID coatings. We help IVD manufacturers develop needles and probes that are coated on the ID to minimize carryover. We also help medical device manufacturers develop microcatheters that are coated on the ID with biocompatible PTFE for use in endovascular surgery.

Contact one of our medical device coating specialists at

(714) 533-3183 or email us at IDcoating@thermech.com.

ID Coating of Hypotubes with PTFE

To download a PDF of our

Hypotube Coating Requirements form,

click on the RED arrow.

Complete the form and

fax it to (714) 533-3420 or

email it to IDcoating@thermech.com

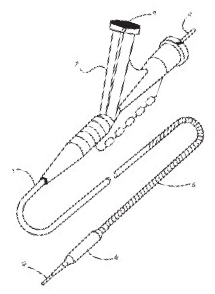

ID-Coated Tubes for Endovascular Surgery

Compared to extruded PTFE liners, coating the ID of microcatheters is a less labor-intensive and more cost-effective method of increasing lubricity.

Maximize lubricity

Hypotubes

Laser-machined hypotubes

Microcatheters

Delivery devices

Balloon catheters

Stent delivery systems

Biopsy devices

Interventional cardiology

Neurovascular intervention

Peripheral vascular intervention

Interventional radiology

Balloon angioplasty (PTCA)

Endovascular aneurysm coiling

Endoscopy

ID-Coated Tubes for IVD

Thermech can help you prevent carryover by applying hydrophobic nonstick Teflon® coatings to the inside diameter of hypotubes used for in vitro diagnostics (IVD). ID-coated needles and probes provide an inert fluid path with Teflon® FEP wetted surfaces.

Minimize carryover

Easy to clean

Needles

Probes

Tubing

Cannulas

In vitro diagnostics

Chromatography

Fluid handling

We also apply coatings to many other parts for the medical device industry, including:

Mandrels

Plungers

Other medical device components

Tips and dies for extruding micro tubing

Teflon® Coating / Spray Coating

Chemours Teflon Industrial Licensed Applicator

Whitford Licensed Applicator

PI / Vespel®

PPS / Ryton®

PES

FILLERS

THERMECH COATINGS

TECfluorcote

TECthermcote

DUPONT™ COATINGS

Teflon® PTFE

Teflon® FEP

Teflon® PFA

Teflon® One Coats

Teflon® PTFE/PFA Blends

WHITFORD® COATINGS

Xylan®

Xylan® XLR

Eclipse®

Dykor®

Xylar®

Halar® ECTFE

Teflon® ETFE

Teflon® FEP

Teflon® PFA

Ryton® PPS

PTFE Etching and Bonding

Home | Quality | Contact | About | History | Aerospace Coatings | Medical Device Coatings | Non-stick Commercial Bakery Coatings

Mold Release Coatings | Teflon® Coatings | Powder Coating | Compression Molding | Spray Coating Materials

Powder Coating Materials | Compression Molding Materials | Privacy Policy | Terms of Use | ©2010 Thermech Corporation. All Rights Reserved.

Teflon® is a registered trademark of E.I. du Pont de Nemours and Company used under license by Thermech Corporation. Only DuPont makes TEFLON®.

1773 West Lincoln Avenue, Building I • Anaheim, California 92801